If you are looking to bring your product idea to life with Canadian design and manufacturing expertise, connect with us. Let’s build at home.

Beyond the Label: Made in Canada

Manufacturing is a cornerstone of Canada’s modern economy, accounting for only around 10% of Canada’s total GDP. The country’s strategic location with access to both North American and global markets, as well as its strong trade agreements, growing local demand, long-standing reputation for quality, safety and innovation, and abundant natural resources makes it an attractive destination for manufacturers.

Recently, product companies have also been reshoring operations due to rising geopolitical tensions, escalating shipping costs, and ongoing global supply chain disruptions, in other words the world is not quite as flat as we were made to believe. These factors are pushing more businesses to explore the advantages of building closer to home—and Canada is stepping up as a strong, stable choice.

But what does “Made in Canada” mean? At NeuronicWorks we are often asked this question from clients and partners who are looking to understand the value and implications of the “Made in Canada” label.

In this blog post, we will explore the meaning of “Made in Canada”, the benefits, challenges and other nuances behind manufacturing in Canada.

“Made in Canada”

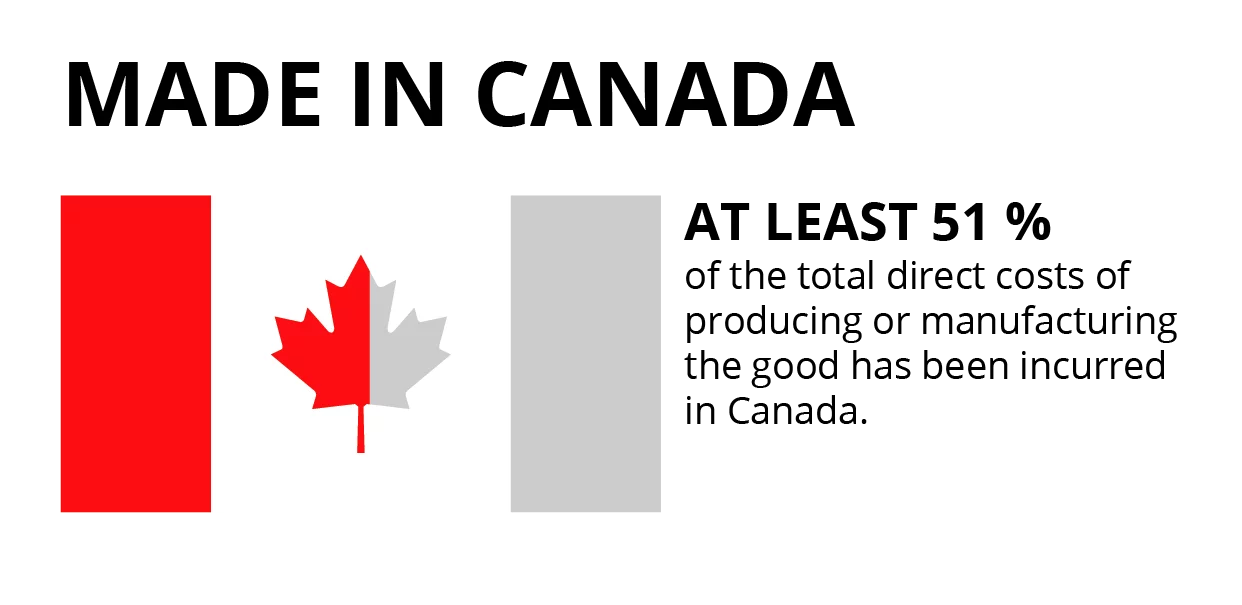

According to the Competition Bureau of Canada, a product can only be labeled “Made in Canada” if at least 51% of the total direct costs of producing or manufacturing the product are incurred in Canada which includes costs like labor, materials, overhead, and manufacturing , and the last substantial transformation of the product occurs within the country. While the definition for substantial transformation can be subjective, determined on a case-by-case basis, assembling parts into a product is considered substantial transformation (processing cheese, flour, sauce, water and other ingredients), while assembling sub-systems into a product is typically not considered as substantial transformation (baked frozen pizza).

It's important to note that the product must also be accompanied by a qualifying statement if not entirely Canadian in content, for e.g., “Made in Canada with imported parts” or “Made in Canada with domestic and imported parts”. This could also include more specific information such as “Made in Canada with 60% Canadian content and 40% imported content”.

Some other distinctions to Made in Canada are:

- Product of Canada: Requires 98% or more of the total direct costs of producing or manufacturing the product to be Canadian and the last substantial transformation of the product to have occurred in Canada.

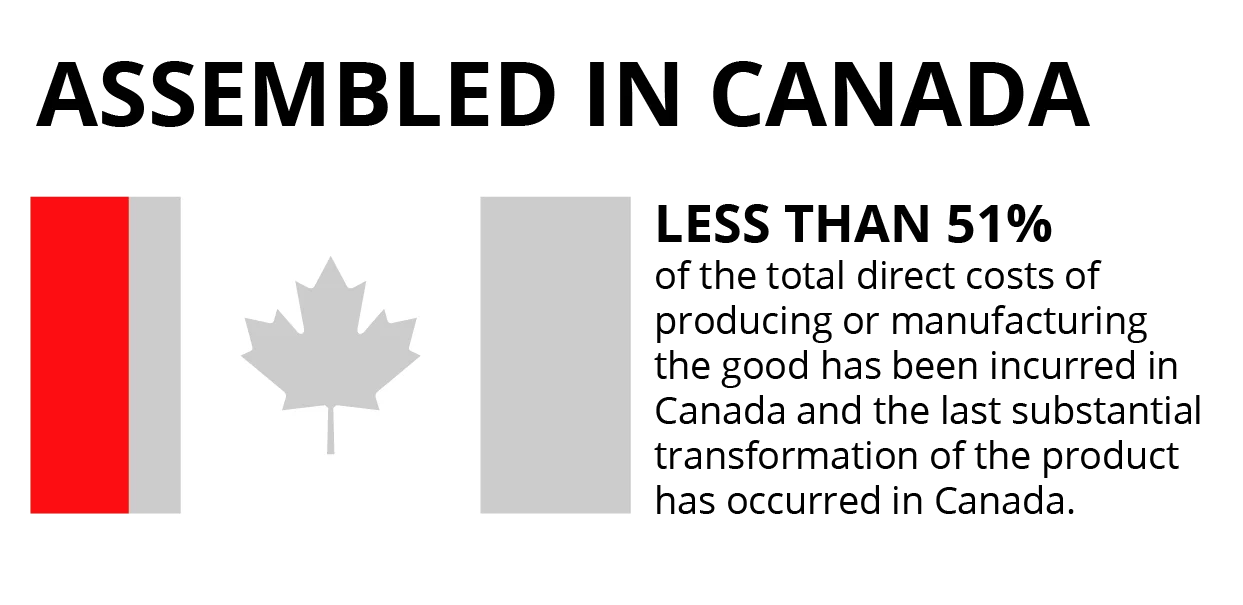

- Assembled in Canada: Requires less than 51% of the total direct costs to have been incurred in Canada and the last substantial transformation of the product to have occurred in Canada. Most or all the components/parts are imported but the final assembly happens locally.

Figure1: Canadian Manufacturing Labels

The “Made in Canada” label fosters a fair marketplace, building trust, strengthening consumer confidence and supporting the local economy. It is also a signal of quality craftmanship and ethical production. For industries like medical devices, aviation and industrial electronics, the label can be a mark of trust and competitive differentiation.

The Complexities of Modern Manufacturing

In today’s global supply chain landscape, Canadian manufacturers rely heavily on international components. For example, a PCB may be fabricated in Asia, but if it's assembled, tested, and programmed in Canada, the PCBA might still qualify as “Made in Canada.” Transparency in sourcing and understanding the cost breakdown is crucial to making that claim accurately.

Building local and regional resilience isn’t just a strategic advantage—it’s a statement of confidence in Canadian quality, sustainability, and innovation. Here are some critical steps to take for building a smarter, resilient supply chain in today’s global landscape:

- Centralize HTS (Harmonized Tariff Schedule) code and Country of origin data

Note: It is crucial that all product sub-assemblies, including wiring, enclosures, modules, fasteners, power supplies, electronic and electrical parts, etc. have a correct Canadian HTS code (CAHTS) or USA HTS code (USHTS) and an official 'Country of Origin' statement on their product pass packaging labels. Some Electronic & Electrical parts distributors will provide the Canadian & US HTS code online, but rarely the recognized 'Country of Origin'. Supply Chain professionals, Component Engineers and Engineering designers will typically have to contact each manufacturer's Customer Support team to receive the stated parts Country of Origin information via email or formal PCN notice. - Integrate data into ERP and sourcing tools

- Automate real-time alerts with reliable sources. The advent of APIs in components sourcing enables automation, integration, and real-time information exchange.

- Plan impact of potential disruptions

- Identify and record backup suppliers or sites for critical parts

- Prioritize Canadian suppliers where possible to improve responsiveness and reduce geopolitical exposure.

- Collaborate with engineering to scope component and BOM alternatives

- Formalize alternate BOMs and get them approved

- Assess timelines and impacts of sourcing under tariff scenarios

- Add contract terms that cover sourcing contingencies

- Foster collaboration across procurement, engineering, logistics, and compliance teams.

- Ensure consistent, accessible data across departments to support agile decision-making.

- Monitor trade policy developments and assess their impact on sourcing strategy.

- Diversify supplier base to minimize exposure to any single region or tariff regime.

1. Document your supply chain process

2. Organize data to guide sourcing decisions

3. Identify secondary suppliers

4. Align your teams and data

5. Reduce tariff risk with a long-term plan

Establish long-term relationships with Canadian component and contract manufacturing partners.

Benefits of Manufacturing in Canada

Manufacturing in Canada is beneficial for multiple reasons and for the entire ecosystem. Here are some clear benefits:

- Abundant Natural Resources: Canada is rich in essential raw materials like metals, minerals, and timber, providing a secure and local source of inputs for various manufacturing sectors. Skilled Workforce: Canada’s workforce offers access to talented engineers, technicians, and R&D professionals especially in the field of technology and engineering.

- Innovation Ecosystem: We have a strong innovation ecosystem promoted by the government and supported by academia and industry.

- Location: We have an advantageous position near the U.S. market, along with trade agreements such as USMCA, which enables entry into world’s biggest consumer market.

- Trade Agreements: Canada also has access to international markets via CETA (Canada and the EU), and CPTPP (Trade agreement with 11 countries across the Asia-Pacific region).

- IP Protection: Canada has robust intellectual property laws promoting product innovation.

- Incentives: The federal and provincial government offer incentives such as tax exemptions, subsidies, grants and tax credits like IRAP and SR&ED to support innovation and R&D.

- Proximity to a Growing Internal Market: Canada's population and economy continue to grow, offering direct access to a stable, high-income consumer base that values locally made products.

Challenges to Consider:

While there is a plethora of benefits, there are also some challenges with manufacturing in Canada. Some of them are:

- Higher Costs: The most significant challenge is that the costs of labor, utilities, and compliance are often higher than in other regions, making it difficult for manufacturers to stay competitive. However, these higher costs often go hand-in-hand with higher quality, accountability, and sustainability.

- Logistics: Shipping and distribution costs can be significant, particularly for export-driven businesses. Efficient planning and working with Canadian logistics partners can help optimize this.

- Regulatory Compliance: Meeting Canada’s stringent and complex regulations and compliance requirements will require diligence and may raise operating expenses, but will lead to safer, more trustworthy products

- Environmental compliance: Canada enforces strong environmental regulations and sustainability practices. Meeting these standards may increase upfront costs but they also align with global environment sustainability trends and consumer expectations.

- Trade uncertainties: Geopolitical tensions and changing trade laws and tariffs can impact manufacturers, particularly those involved with exports and global supply chains. Diversifying suppliers and sourcing more from within Canada can help mitigate this risk.

Ensuring Compliance with the “Made in Canada” Standard

To confidently use the “Made in Canada“ label, product developers must take a disciplined and transparent approach to sourcing, documentation and production processes. Here’s how:

- Detailed cost analysis: Keep accurate and dated records of the direct costs of production which includes labor, materials, manufacturing, and overhead incurred in Canada. Being able to demonstrate that at least 51% of these costs originate domestically is critical.

- Supply chain traceability: Implement traceability mechanisms to document where each component or material is sourced from. This not only supports compliance but also builds trust with customers and regulators.

- Final Transformation in Canada: Ensure that the last substantial manufacturing process (e.g., assembly, programming, testing) happens within Canada. This step is essential for qualifying under the labeling rules.

- Labeling and Claims Management: If the product doesn’t meet the full requirements for a “Made in Canada” claim, use qualifying statements such as “Made in Canada with domestic and imported parts” to stay compliant and transparent.

- Work with local Experienced Partners: Collaborate with Canadian contract manufacturers like NeuronicWorks who understand the regulatory landscape. Our experience can be valuable in avoiding mistakes that could damage brand credibility with regulators and customers.

Manufacturing in Canada is more than just about a label, it is a commitment to quality, innovation, transparency and ethical practices. It is a commitment to the future of Canada!

At NeuronicWorks, we design and manufacture products for our customers that are proudly “Made in Canada”. We work closely with our customers to ensure compliance with the labeling requirements, maintaining documentation and processes that can withstand regulatory scrutiny, and yield quality products that set our customers up for success.