Would you like to see your product vision take on a sleek, trendy, smart form with an ideal user experience? Take advantage of our team’s expertise in designing innovative industrial designs for applications like wearables, automotive, medical, industrial and consumer electronics to name a few. Get in touch with us today to know how we can help you realize your product design from concept to deployment.

What is Industrial Design? And why should you care about it?

“So, you’re an industrial designer? That’s cool! What do you do, exactly?

I get this question a lot.

I think the word ‘Industrial’ is what throws people off. On hearing the word ‘industrial’, people typically visualize large warehouses and industrial equipment. It is only when I explain that industrial designers envision new products for a living, that their ears perk up and they get excited.

So, what is Industrial Design?

Here is the technical definition : Industrial Design(ID) is the professional practice of designing products, devices, objects and services used by millions of people around the world every day.

Industrial Designers creates the envelope of a new product and also of its internal contents that aims to be both functional and aesthetically pleasing. We have a keen sense of observation and pay attention to minute details which most people wouldn’t immediately consider. Why are the buttons on a remote silicone? Why did they use this icon? Why is this plastic? Why is it metal? What surface finish is this? How can we improve this? How do we optimize these parts? These are some of the questions that we as industrial designers constantly ask ourselves and bug our colleagues with. We obsess over the little details that would often go missed by others. The colors, shape, surface finish, materials, usability and ergonomics of everyday products are some of the elements that we lose sleep over.

What do Industrial Designers do?

We are known for being creative problem solvers.

Our sense of 3D spatial thinking and utility savviness, helps us deliver innovative solutions to our clients’ product requirements. We use a multitude of digital and physical mediums to create and help visualize key features of everyday products. Everything from form, aesthetics, ergonomics and user interface (UI) falls under the industrial design umbrella.

Key factors industrial designers are responsible for:

- Research of target markets and end-users.

- Physical appearance of the product.

- Functionality of the product.

- Manufacturability of the product.

- Sketch, model and build mockups to generate ideas and solutions to problems.

- Generate digital designs using CAD program.

- Research and source appropriate materials, manufacturing processes and estimate cost requirements.

- Blend form and function to achieve manufacturable and practical solutions.

- Present and discuss ideas with clients.

Industrial Design is an iterative process, most of the actions listed above are repeated in successive design cycles, until an optimal form, function, aesthetics, manufacturability equilibrium is reached, and the client is thrilled.

What is the Industrial Design process?

The industrial product design process is not written in stone and will vary depending on the client’s style, requirements of the product and even the designer’s approach, but it will be more-or-less a version of the following steps.

Define the “why” and the “who”

Why do we want to develop this product? What problem is this product solving? What is the intended market for this product? Who is the end user? This is step 1 for a good reason, and it will dictate the direction of everyone involved in the project. No matter the stage in the design process, we can always come back and say, “This is the reason why we are trying to solve this problem”.

Research

Spend time in identifying current trends, look for inspiration, study competitive products and research the attractive features of pre-existing products in the market.

Ideate

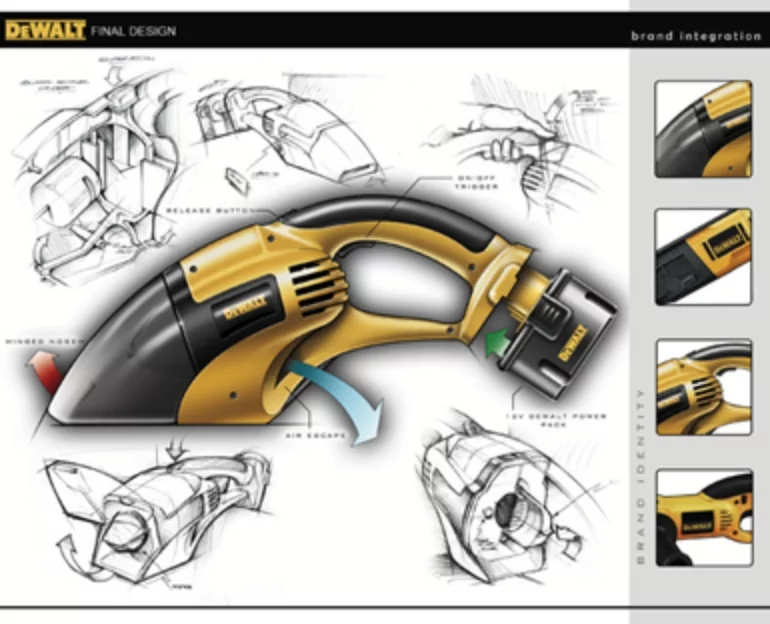

This is where the magic happens. This is where we begin to sketch out and lay it all out on the table (or whiteboard!). This is where the seed of the solution to the problem begins to take root. Throw everything at the wall: as many ideas as possible, even the ‘crazy’ ones. Restrictive and hierarchical environments stifle valuable ideas. There’s as much value in knowing what will not work, than what will work.

Prototype

In my opinion, this is the most fun part of the design process. This is where the solutions begin to take shape - literally. We use 3D prints, clay, foam and cardstock just to create models to physically hold in our hands. At this stage, the idea shifts over from a design we see on screen or paper, to a product in our hands that we can physically interact with.

Test and document

Once we have all our prototype parts together, we can assemble them and start to validate our design. We can conduct comprehensive testing to see what might have been missed in the design process and how users will actually use our product. We make sure to document everything so we can go back and assess what went right and wrong.

What tools do Industrial Designers use?

Sketching / Renderings

One of the best and most important tools that designers have is the good ol’ pen and paper. Start analog; Getting a few sheets of paper and a ballpoint pen can really kick start the creative process. There is no faster way to get ideas out of your head and onto paper, than a quick sketch. These are not masterpieces...their purpose is strictly to convey the designer’s ideas. This analog part is where a good portion of the brainstorming happens. After the “napkin sketch” is thoroughly thought out, we can move on to digital media or physical prototypes.

Computer-Aided Design (CAD) programs

Digital media or CAD modeling programs are widely used in the industry. Programs such as Solidworks, Fusion 360, Keyshot, CATIA and the Adobe Suite are some of the programs industrial designers use daily. CAD programs allow us to dive into the details of the design and start bringing it to life. We use these tools to help identify sizing, dimensions, materials, and component placement. CAD programs take the guesswork out of complex system integration, they help us to integrate complex systems and bridge the gap between electronic PCB design and the mechanical design of the product. In our industry, they go hand-in-hand.

Physical Prototypes and Mock-Ups

Physical prototypes are some of the best ways to precisely identify what works and what does not in a product. There is no substitute for a good working prototype that we can physically interact with. I mean, at the end of the day, we are designing physical products, so it would only make sense to prototype! Prototypes can be made from just about any materials- foam, clay, silicone, plastics, and the ever-popular 3D printing.

3D printing has made great strides in a very short amount of time. Once we build a digital model for our product, we can have it 3D printed and start testing in a matter of days. This helps in cutting down the development time significantly by reducing the number of product iterations.

What industries use Industrial Designers?

I think the list of industries that do not use industrial designers would be shorter, but here are a few that you may or may not know of:

In recent years, industrial designers have migrated to the world of UI/UX design. We have a great understanding of how users interact with products, and that translates well into the digital world of how users interact with Apps and UI interfaces. Industrial designers and UX designers share a common goal: to enhance the user experience. Whether it be digital or physical, the designer wants to create the best user experience possible.

Why is Industrial design important?

Good industrial design will evoke a memorable reaction or emotion from the user. It helps the user connect and bond with a particular product.

If you’re standing in front of a shelf with 5 different products, and you instinctively reach out to grab one, that is because of good Industrial Design.

We develop aspects of a product that create emotional connections with the user. In the design, we integrate all aspects of form, fit and function while optimizing them to create the best possible user experience.

Today, the demand for good Industrial Design has significantly increased in the digital and physical world. Companies see the value in designing a solid, well-designed, user friendly product. Understanding of user behavior, ergonomics, shape, color, materials, finishes, manufacturing, and function are key elements of any successful product.

We are the link between mechanical engineers, electrical engineers, project managers, marketing professionals and the end-client.

A lot of times, we find ourselves at the meeting table listening a lot more than speaking. I find myself digesting information from clients and trying to reiterate it in a way that everyone can understand.

Communication is key to meeting the needs of the customer.

This happens more often in the industry than one may think and to avoid it, we make every effort necessary to clarify and communicate clearly and early with our clients. One of our key values at NeuronicWorks is “Talk numbers, not adjectives''. We ask the redundant and obvious questions to make sure everyone is truly on the same page.

So back to our original question “Why should you care about industrial design?”

Because industrial design is all around you. You interact with it every day. Whether you handle your phone, open a car door, listen to music through headphones, go out for a workout in your sports shoes or sit in a chair, you have interacted with a product that an industrial designer had envisioned.

There is a reason you bought this product, rather than that one. This product feels more comfortable than that one. Something made you buy it, regardless of cost. You chose a product that evoked some type of emotion. Happiness, comfort, usability, durability, the feel, the form, the color, whatever it is, there is a reason your eyes, and hands went for it. And more often than not, an industrial designer had an important part to play in the development of that product.