X-ray Inspection Service

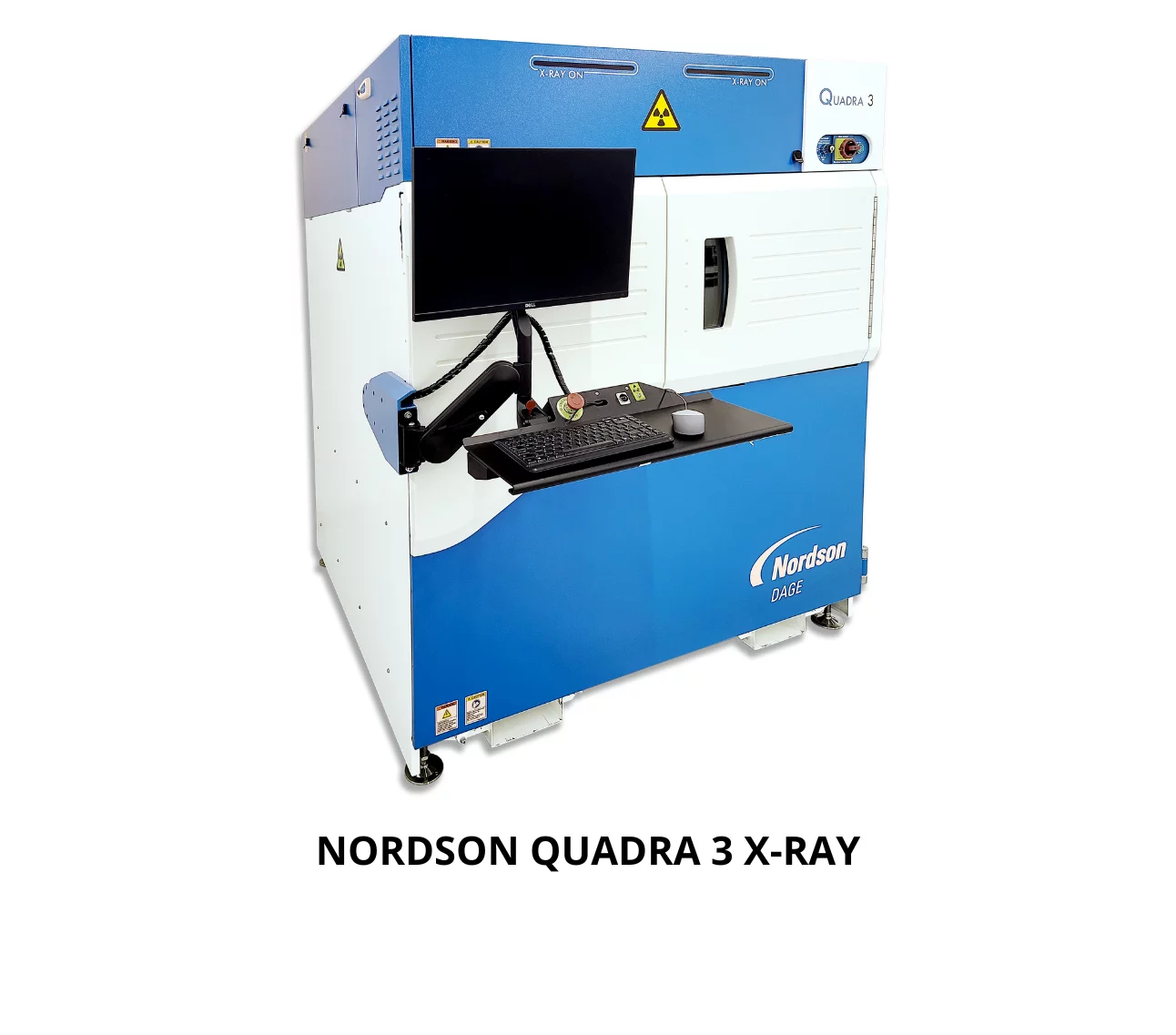

NeuronicWorks offers 3D X-ray inspection services using the NORDSON DAGE Quadra 3 X-ray inspection system for printed circuit board assemblies.

Some of the issues that can be detected include lifted lead, missing components, misaligned/misplaced components, solder bridges, insufficient solder, solder voids, excess solder, BGA shorts, improper reflow soldering and more. In addition to detecting issues in the PCB Assembly, the X-ray reports and determines the root cause.

The type of components we can inspect include BGA, LGA, leadless components with exposed pad (UFDFN, VFDFN, WFDFN, VFQFN, TFQFN, WFQFN, LFCSP-UD, WLCSP, XFBGA) DFN, QFN, and all other complex components.