X-ray Inspection Service

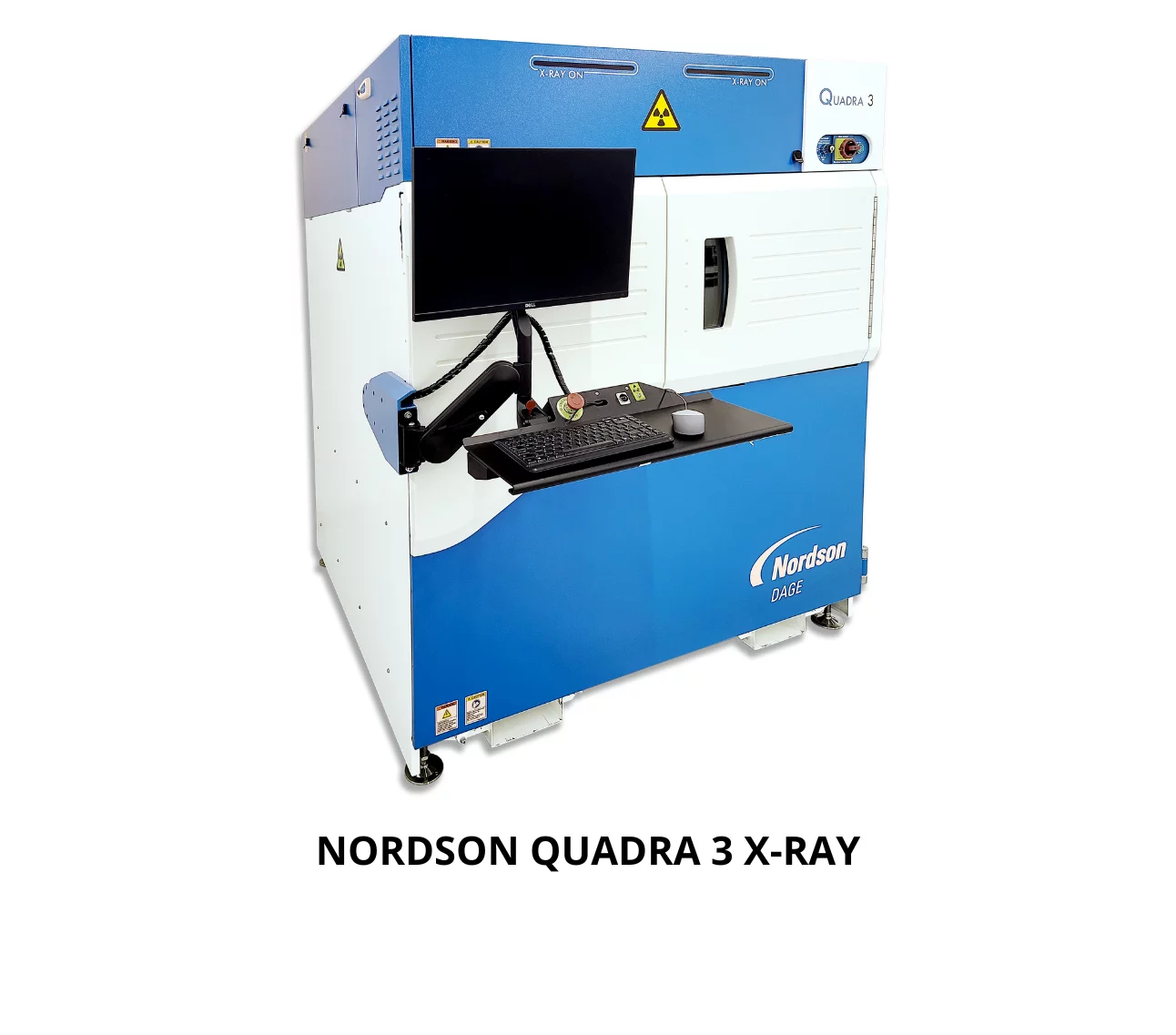

NeuronicWorks offers 3D X-ray inspection services using the NORDSON DAGE Quadra 3 X-ray inspection system for printed circuit board assemblies.

Some of the issues that can be detected include lifted lead, missing components, misaligned/misplaced components, solder bridges, insufficient solder, solder voids, excess solder, BGA shorts, improper reflow soldering and more. In addition to detecting issues in the PCB Assembly, the X-ray reports and determines the root cause.

The type of components we can inspect include BGA, LGA, leadless components with exposed pad (UFDFN, VFDFN, WFDFN, VFQFN, TFQFN, WFQFN, LFCSP-UD, WLCSP, XFBGA) DFN, QFN, and all other complex components.

KEY FEATURES

X-RAY INSPECTION SYSTEM:

- Feature recognition: 0.95 µm

- Resolution: 1.4MP

- Frame Rate: 10fps

- Inspection area: 510 x 445mm (20 x17.5”)

- Geometric Magnification: 2000x

- Total Magnification: 7500x

- Oblique Angle View: 2x70° - No sample rotation required

equipment

Our NORDSON DAGE Quadra 3 X-ray inspection system is specifically designed for high-resolution X-ray inspection in printed circuit board assembly production applications. Delivering uninterrupted operation at 0.95µm, the system is suitable for detecting a wide range of manufacturing defects including BGA, QFN and IGBT attachment, PTH filling, interfacial voiding, component cracking and counterfeit devices screening.

We provide quick turnaround X-ray inspection services to customers who walk-in, have scheduled appointments or connect remotely via Zoom or Teams meetings (the boards can be shipped to us directly for this service).

other related services

- PCB Assembly

- PCB Repair

- PCB Assembly Washing

- Conformal Coating

- Testing in Thermal Chamber

- Potting

- Encapsulation (To be launched at the end of Q4 2025)

- Laser Cutting

- Laser IC marking removal

- Box Build Assembly