PCB Assembly

NeuronicWorks offers turnkey PCB Assembly services for prototype and low to high volume manufacturing from our facility in Toronto, Canada. We manage end-to-end PCB Assembly from procuring bare printed circuit boards and electronic components, material management (purchasing, receiving and kitting), through to SMT assembly, through hole, testing, PCB repair and BGA rework as required. Our team also assists with component replacement to address obsolete or out-of-stock parts. We also perform DFX review for continuous improvement of your product.

Turnaround time:

- Rush orders: 1-2 days

- Prototype: 3-7-10 days

- NPI: 10-15 days

- Production: Depends on pre/post-processing tasks: 15+ days

(TBD based on volume)

Capabilities

- Manufacturing file format: Gerber, BOM, Pick and Place/XY file, ODB++

- PCB Assembly types: Rigid, Flexible, Rigid-Flex

- Board types such as FR-4 multi-layer, FR-4 rigid, flex circuit, rigid flex, polyimide

- Board finishes such as OSP, ENIG and HASL

- Mixed Technology: Surface Mount Technology (SMT) and Through-hole (THT)

- No clean/clean solder, RoHS 3 (Lead-free) Compliant Assembly Process

- DI water-wash process

- Single or double-sided placement

- BGA, μBGA, QFN, QFP, POP, 3D cavities, Lead frame, Pre-mounted, Pin-in-Paste, Broadband, Flat chips

- Smallest size components 0201

- Proper handling of MSL (Moisture Sensitivity Level) components

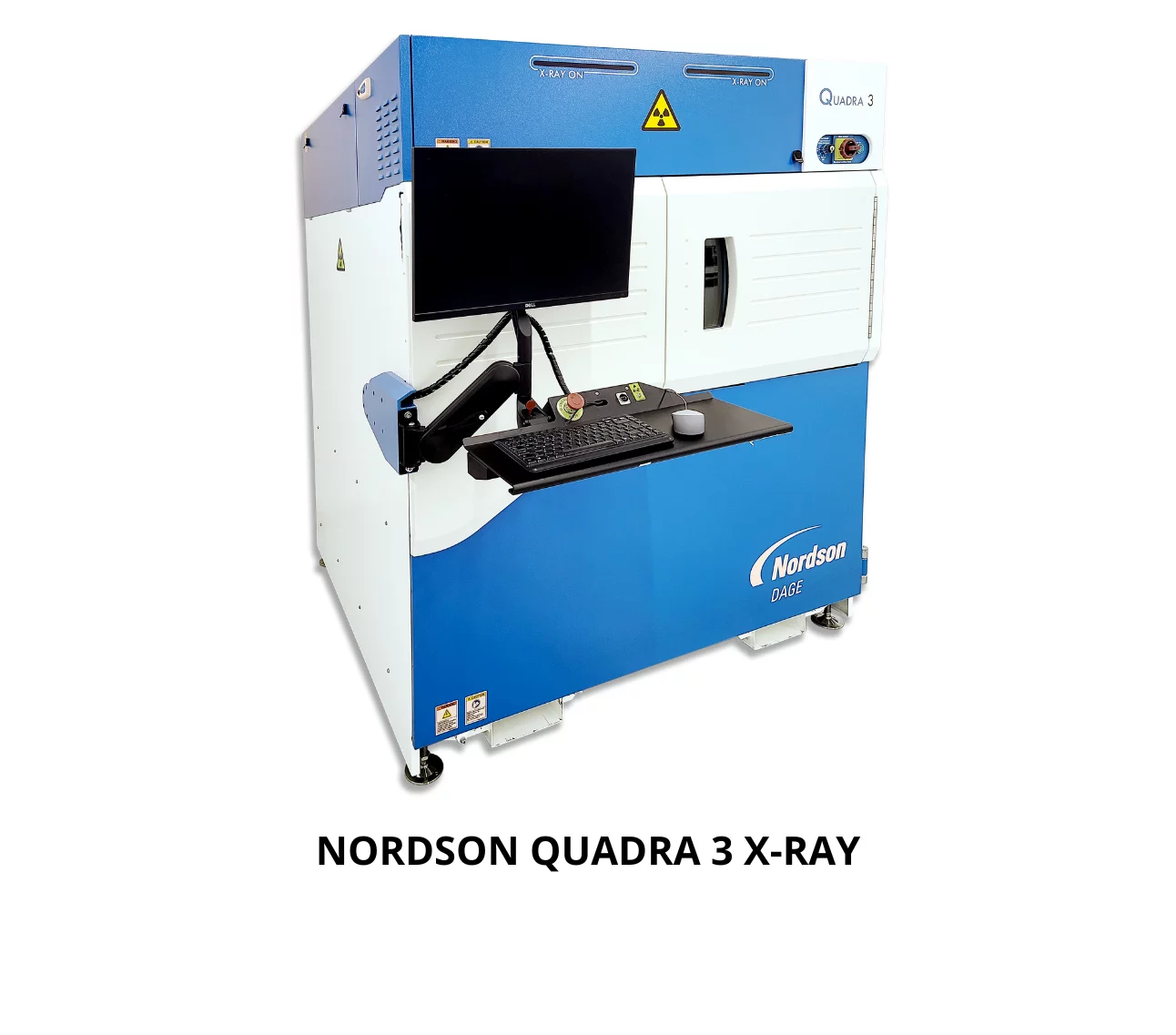

- 3D X-Ray Inspection

- 3D AOI (Automated Optical Inspection)

- Depanelization system (V-score and Mouse-bites)

- PCB Assembly Repair

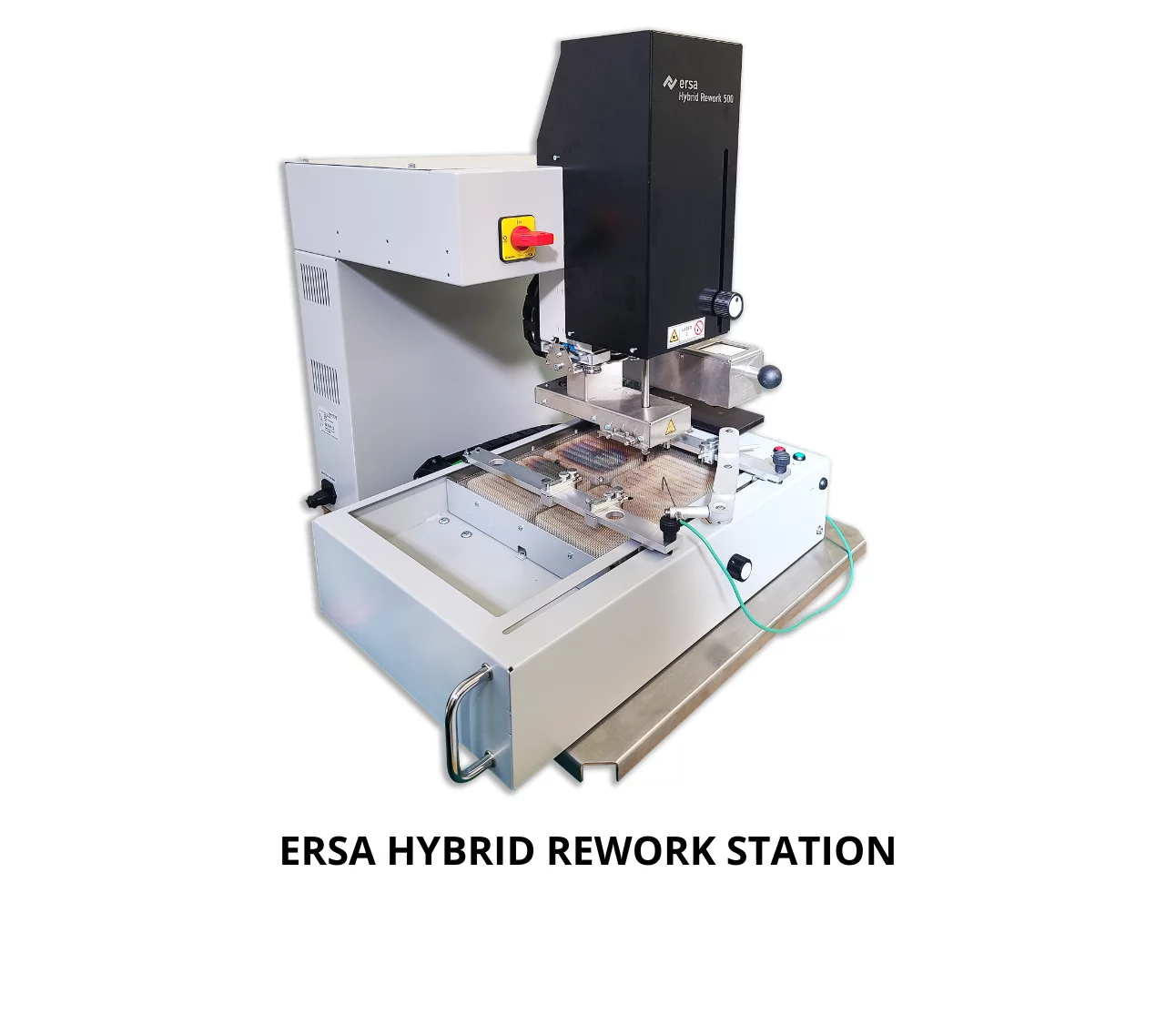

- BGA Rework

- DFX Review:

- Design For Manufacturing (DFM)

- Design For Assembly (DFA)

- Design For Cost (DFC)

- Design for Supply Chain (DFSC)

- Design For Reliability (DFR)

- Parts procurement: Full turnkey, partial turnkey, consigned

- Material Management (procurement, receiving, inventory and kitting)

- Ready-to-use standard inventory of in-house components (MyWorks)

Certifications

• ISO 9001: 2015

• IPC A-610 Class 3 capability

• RoHS Compliant

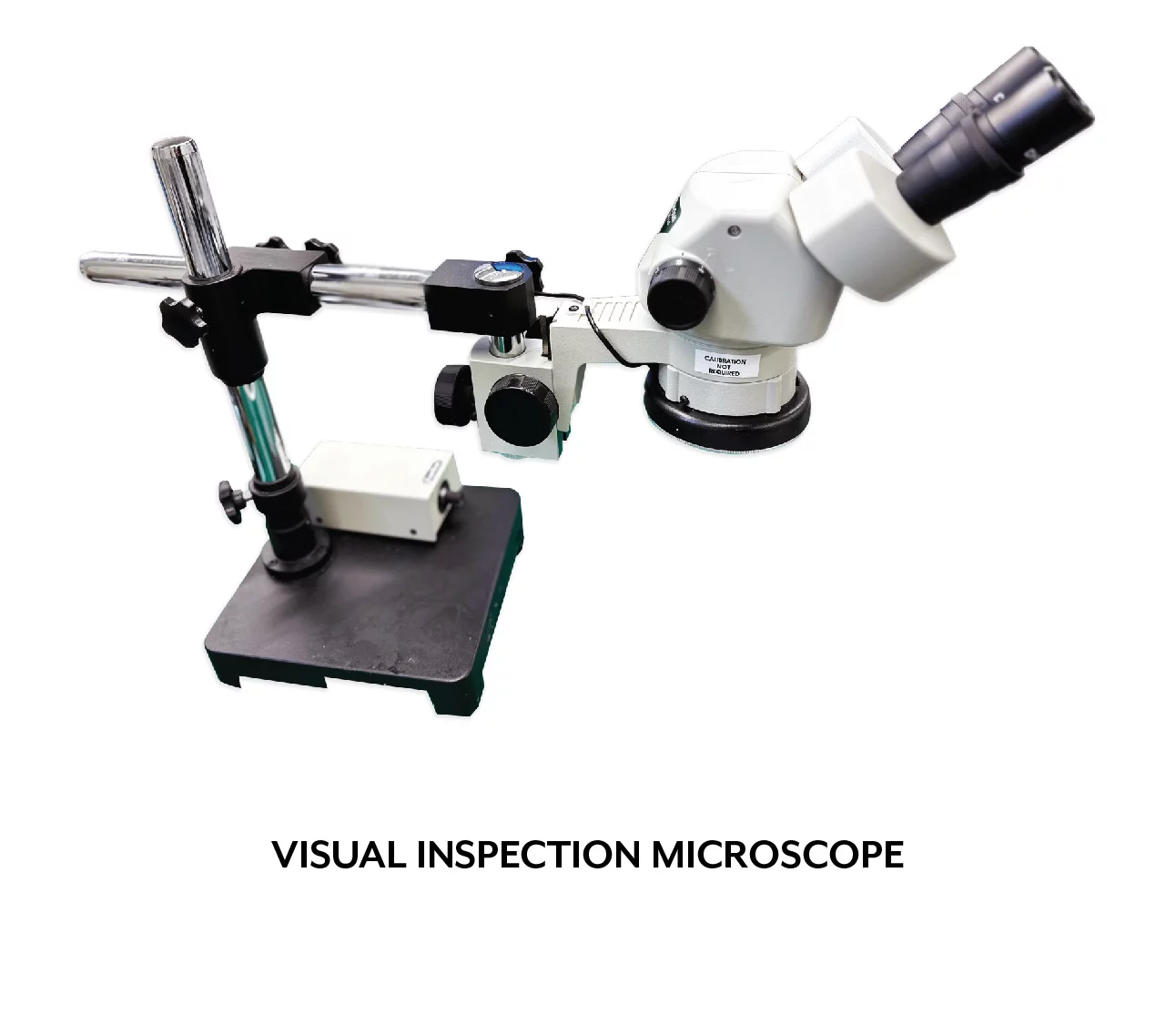

Equipment

Our state-of-the-art facility provides PCB assembly services using the latest SMT Assembly technology and equipment to deliver great results.

Quality Control is achieved through detailed processes, inspection and validation of assembly work through 3D AOI, X-Ray inspection and final PCB assembly visual inspection.